Table of Contents

Custom extrusion is a great way to create plastic or metal parts. It is flexible, clean, and made of different materials and molds. You can use aluminum, plastic, or other metals to create your desired product. Of course, the choice of raw materials will depend on your needs and the cost.

Aluminum

Aluminum extrusion is the process of forming aluminum into a variety of shapes. The process is most popular in the food and beverage industry. Aluminum extrusion produces a very lightweight material, which can be shaped into thin structures. Additionally, the process can be recycled once it has been used.

Aluminum extrusion is a relatively simple process. It starts by pressing the aluminum sheet into a die and pulling it out along a runout table. The force needed to extrude aluminum is similar to the point that squeezes a tube of toothpaste. The opening of the tube serves the same purpose as the extrusion die. Using this same principle, a solid circle will produce a long, solid extrusion.

Plastic

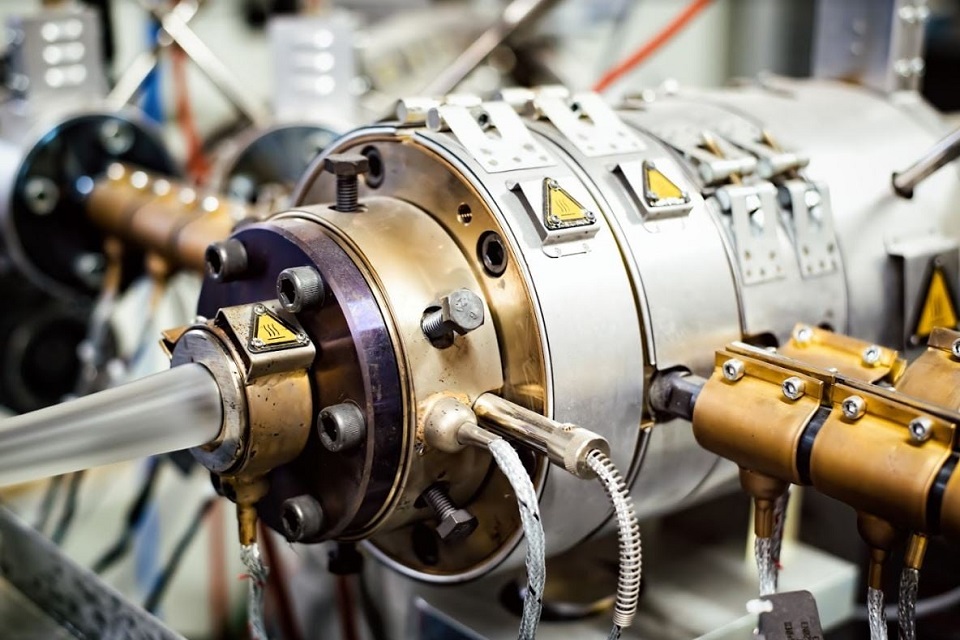

Plastic extrusion is a manufacturing process that creates products in various shapes, sizes, and materials. The process begins with the material being introduced to the front flange of a die and flows around a metal parting tool called a mandrel. The mandrel is supported by a pin and land that is removed when the part leaves the die. The material is then passed through a cooling process to remove any stresses.

Extrusion has been around since the early 19th century. It was first used to create rubber products by Thomas Hancock, who invented a rubber masticator. His two-roll rubber mixing machine was later adapted to plastic materials.

Stainless Steel

Whether you need small components or high-volume production runs, a custom extrusion manufacturer can help you find the perfect solution. These companies offer a variety of extrusion processes, from bending to deep drawing. They can also provide secondary services such as polishing and electroplating.

Stainless steel is a low-maintenance material that can be easily cleaned and sterilized. Its low thermal and electrical conductivity also makes it an excellent choice for sanitary applications. However, its low flexibility makes it difficult to extrude, which means its shapes must have thicker walls and corners.

Brass

Brass custom extrusion is a versatile manufacturing process for forming and stamping metal parts. It is available in various shapes and sizes and can meet ANSI and Mil-spec requirements. It can also be made to meet your specifications by using secondary operations such as anodizing, drilling, and pad printing.

Custom brass and bronze extrusions provide cost-effective solutions for diverse industrial needs. They can be used in architectural shapes, decorative fixtures, furniture frames, and electrical components.

Copper

Copper extrusion is an important technology used to produce high-precision copper strips. This process is beneficial in many fields. It is highly energy-efficient and environmentally friendly. It is replacing traditional methods of making copper belts and has a long-term, promising application future. This article reviews the fundamentals and advantages of this process.

The process involves several phases, and the end product is typical of high quality. It uses state-of-the-art machinery and requires strict quality control procedures.

Zinc

Zinc custom extrusion is a process that involves forming metal rods from zinc. These rods can be fabricated into any shape or size. These custom metal rods are ideal for marine applications. They are available in various lengths and diameters and meet the MIL-A-18001 standards. These metal rods have various options, such as stamped flat ends, threading, grooving, and more.

Custom zinc extrusion manufacturers can manufacture zinc-plated rods, coated rods, and threaded fasteners for industrial, commercial, and decorative uses. Their zinc alloys meet AS standards and can be supplied in various shapes, dimensions, and materials. In addition to custom extrusion, they can provide other services such as deburring, honing, grinding, polishing, chem-milling, and mechanical testing.

No Comments